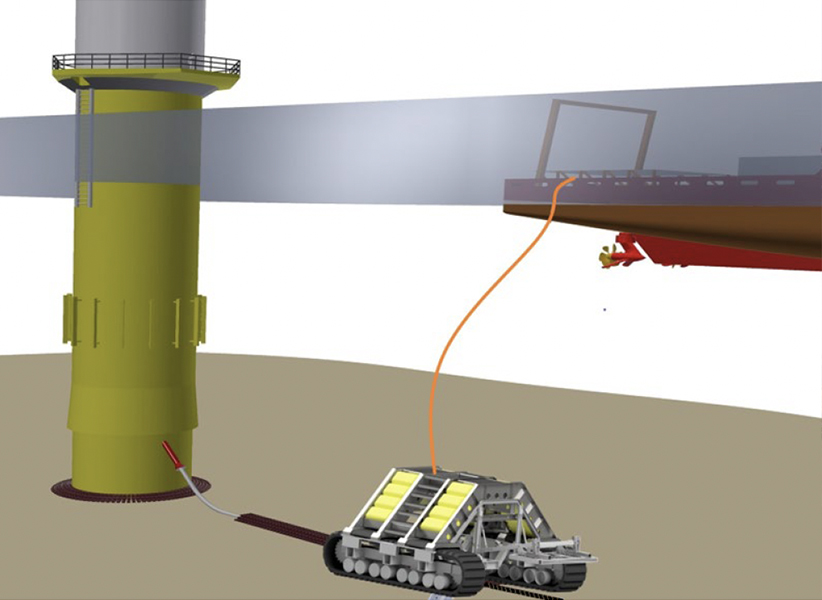

SUBSEA TRENCHER

The trencher is equipped with a comprehensive suite of subsea assets designed to effectively detect and manage cable systems. These include:

Together, these components provide a robust and reliable solution for subsea cable detection and management, ensuring high efficiency and precision in underwater operations.

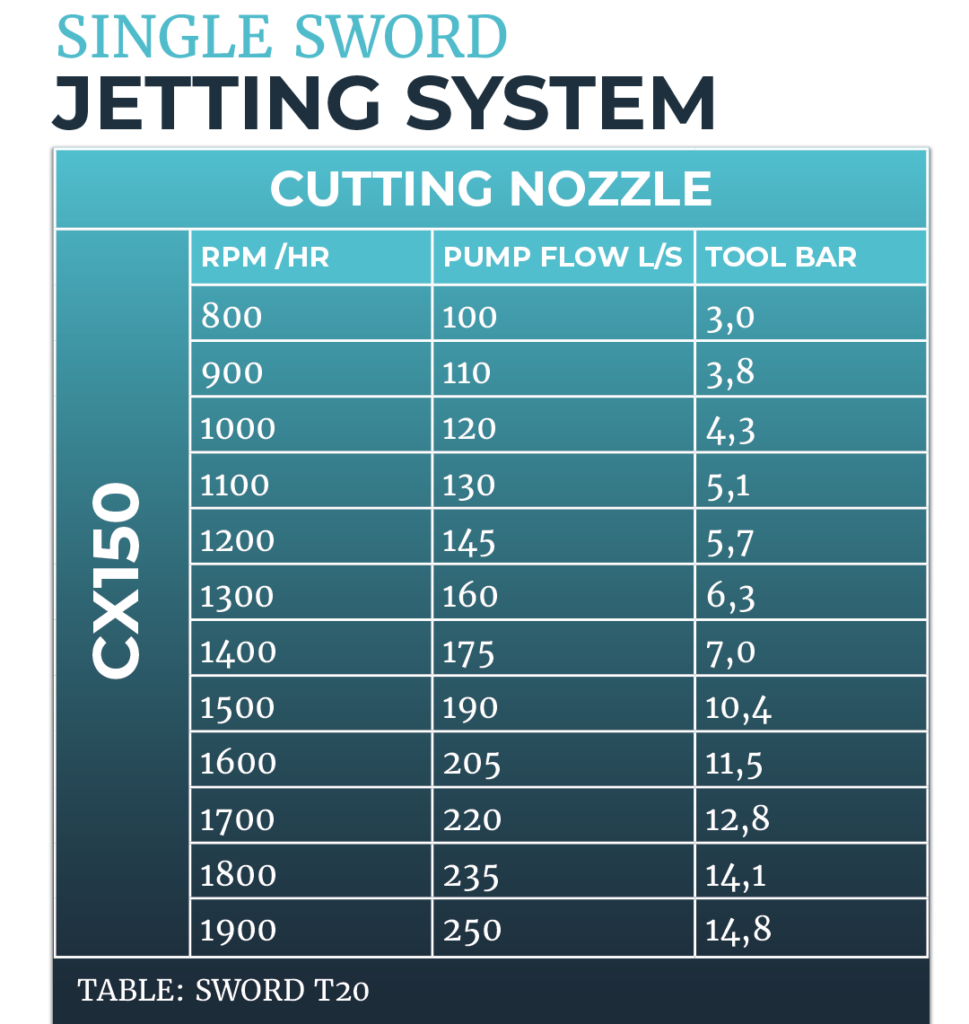

Our single sword jetting system is engineered for unparalleled efficiency and safety in cable burial operations. Whether dealing with surface-laid cables or cables that are self-buried or partially buried, our system ensures secure burial without the risk of damaging the cable.

The system reduces the risk of gathering and pushing slack cable ahead of the jetting system thus reducing risk of infringing the minimum bending radius.

The system stands out for its precision, efficiency, and adaptability, making it the ideal choice for secure and reliable cable burial in various marine environments.

DKM´s preferred sword system T20 can deliver 14 bar at the cutting nuzzles, with a flow of 880m3/h. The vehicle has 820 hp in total.

Customer service

+45 50 16 00 86